The following informations need to be specified when a band saw blades is ordered:

Product name – Lenght x width x thickness – teeth per inch

For example: GMT Viper 6800 mm x 34 mm x 1,07 mm x TPI

STEP #1 ANALYZE THE SAWING APPLICATION

Machine: determine the band size of machine

(Lenght x width x Thicknes).

Material: determine the following for the material to be cut:

1) Material type/grade

2) Size

3) Shape

4) Will material be stacked/bundled, or cut one at a time

Operation: is this a production or general purpose sawing operation?

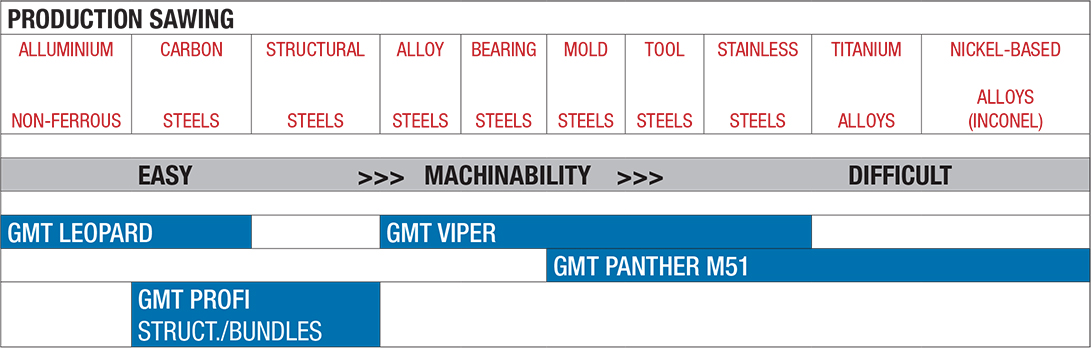

STEP 2#: DETERMINE THE BEST PRODUCTION FOR THE APPLICATION

Use the chart below.

1) Locate the type of material to be cut in the top row

2) Read down the chart to find which blade is reccomended

STEP #3: DETERMINE THE PROPER NUMBER OF TEETH PER INCH (TPI)

1) Use the Bi-Metal tooth selection chart

STEP 4#: CONFIRM THE DESIRED PRODUCT IS AVAILABLE

1) Go to the product page for the product you have select

2) Confirm that product is available in the correct blade width and TPI

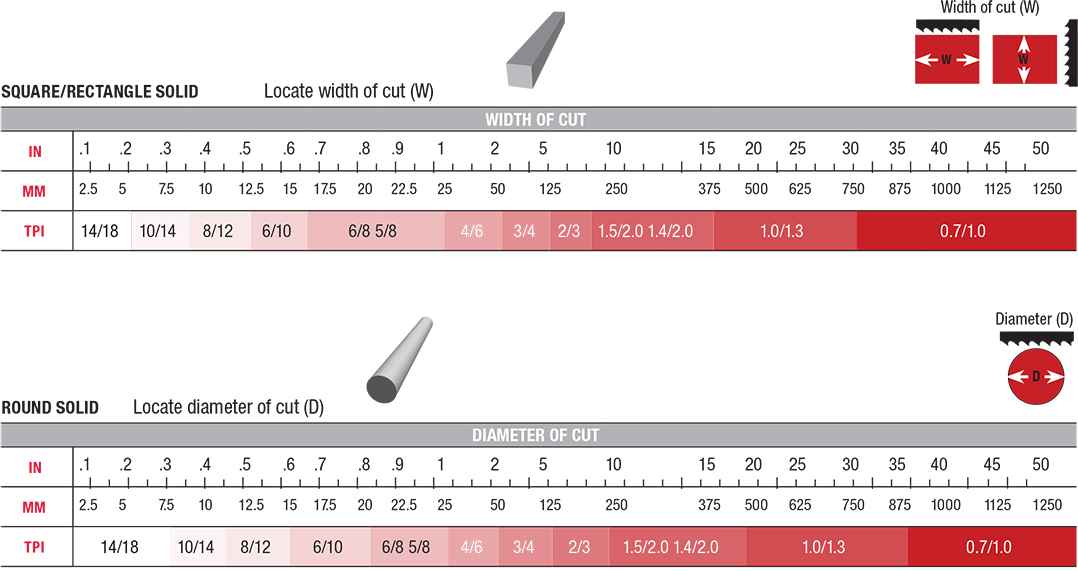

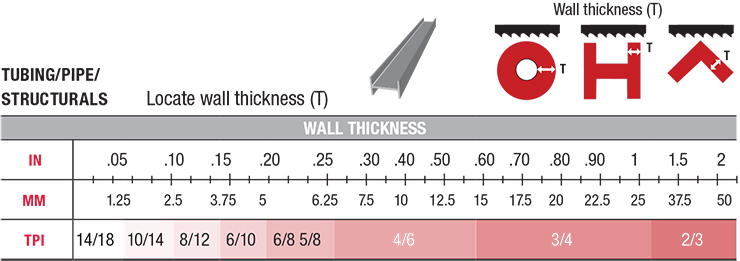

BI-METAL TOOTH SELECTION

1. Determine the size and shape of material to be cut.

2. Identify the chart to be used (square solids, round solids, or tubing/structurals).

3. Read teeth per inch next to material size.

recommended TPI for a single

piece and choose

To select the proper number of teeth per inch (TPI) for bundled or stacked materials, find the recommended TPI for a single piece and choose one pitch coarser to cut the bundle

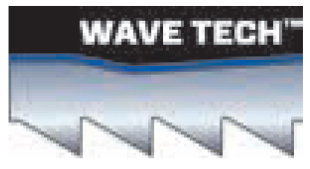

WHAT IS WAVE TECH?

This enhanced mechanical design promotes more efficient tooth penetration and chip formation, easily cutting through the work hardened zone. The WAVE TECH symbol denotes any product that can utilize the WAVE TECH process. Consult your GMT Technical Representative to determine if WAVE TECH will benefit your operation.